PeakPower High LDT Low GDD Ultrafast Mirrors

PeakPower High LDT Low GDD Ultrafast Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- High Femtosecond Laser Damage Threshold exceeding 0.75J/cm2 for 25fs Pulse Duration at 920nm

- > 99.5% Reflectivity with Near Zero Group Delay Dispersion

- Ideal for Advanced Femtosecond Laser Applications

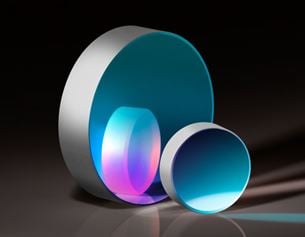

Broadband Dielectric ZERODUR® λ/10 Mirrors

Broadband Dielectric ZERODUR® λ/10 Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- ZERODUR® Substrates Provide Near Zero Thermal Expansion

- Enhanced Reflectivity and LDT over Metallic Coatings

- UV, Visible, and NIR Reflective Coatings Designed for 0-45° AOI

- Metallic Coated ZERODUR® Mirrors Also Available

UltraFast Innovations (UFI) EUV/XUV Attosecond Multilayer Mirrors

UltraFast Innovations (UFI) EUV/XUV Attosecond Multilayer Mirrors

- Designed for 330 Attosecond Pulses @ 65eV (19nm)

- Multilayer Coating with 38% Peak Reflectivity

- ≤1Å (Angstrom) Surface Roughness Superpolished Substrates

- EUV Flat Mirrors and EUV Spherical Mirrors Designed at 13.5nm Also Available

- Available from Stock

- No Minimum Order Quantities, No Coating Lot Charges

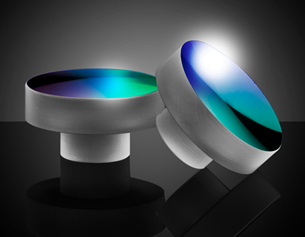

Stemmed Laser Mirrors

Stemmed Laser Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Stemmed Design Reduces Stress on Mirror Surface when Mounted by Stem

- >99% Reflectivity at Standard Laser Wavelengths

- 10-5 Surface Quality for Reduced Scatter in Sensitive Laser Applications

- TECHSPEC® Broadband Dielectric and Metallic Coated Stemmed Mirrors Also Available

Low Cost Nd:YAG Multi-Line Mirrors

Low Cost Nd:YAG Multi-Line Mirrors

- Nd:YAG Harmonic Wavelengths

- >97% Reflectivity at 266, 355, 532 and 1064nm

- Excellent Cost to Performance Ratio

- Nd:YAG Laser Line Mirrors and Low Cost Laser Line Mirrors Also Available

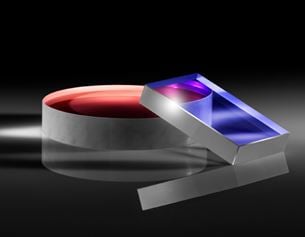

Nd:YAG Laser Output Couplers

Nd:YAG Laser Output Couplers

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Designs for 532nm and 1064nm Nd:YAG Lasers

- 80% Reflectivity at Nd:YAG DWL

- UV Fused Silica Substrates

Ultrafast-Enhanced Silver Laser Mirrors

Ultrafast-Enhanced Silver Laser Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Reflectivity >99% at 600 – 1000nm or 800 – 1150nm

- Low Group Delay Dispersion as Low as 0 ±20fs2

- Ideal for Ti:sapphire and Yb:doped Lasers

- Standard Imperial Sizes Available

- TECHSPEC® Ultrafast-Enhanced Silver Concave Laser Mirrors Available

Yb:YAG Laser Line Mirrors

Yb:YAG Laser Line Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- >99.8% Reflectivity at Yb:YAG Harmonic Frequencies

- Guaranteed High Laser Damage Thresholds

- 10-5 Surface Quality for Reduced Scatter in Laser Applications

- TECHSPEC® Laser Mirror Substrates and TECHSPEC® Nd:YAG Laser Line Mirrors Also Available

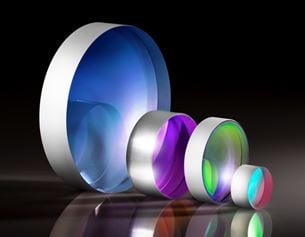

Nd:YAG Laser Line Mirrors

Nd:YAG Laser Line Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

Top Seller

- Up to 99.9% Reflectivity at Nd:YAG Harmonic Frequencies

- High Laser Induced Damage Threshold Specifications

- 10-5 Surface Quality for Reduced Scatter in Sensitive Laser Applications

- TECHSPEC® Laser Mirror Substrates and TECHSPEC® Yb:YAG Laser Line Mirrors Also Available

UltraFast Innovations (UFI) 780 and 800nm Highly-Dispersive Ultrafast Mirrors

UltraFast Innovations (UFI) 780 and 800nm Highly-Dispersive Ultrafast Mirrors

- Reflection >99.8% (P-polarization) at 720 – 840nm or 780 – 830nm

- Low Group Delay Dispersion at 5° or 20° AOIs

- Ideal for Pulse Compression of Ti:sapphire Ultrafast Lasers

- Low GDD Mirrors Also Available

Laser Line λ/20 High Tolerance Right Angle Mirrors

Laser Line λ/20 High Tolerance Right Angle Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- >99.5% Reflectivity at the Design Wavelength

- ±15 Arcsecond Angular Tolerance

- High Thermal Stability Substrates

UltraFast Innovations (UFI) 45° AOI Ultrafast Chirped Mirrors

UltraFast Innovations (UFI) 45° AOI Ultrafast Chirped Mirrors

- High Reflectivity and Negative Group Delay Dispersion (GDD)

- Ideal for Dispersion Compensation and Beam Compression @ 45° AOI

- Designs for Femtosecond Lasers, Including Ti:sapphire

Knife-Edge Pickoff Mirrors

Knife-Edge Pickoff Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Designed to Separate Two Beams Propagating Closely Next to Each Other

- 45° Bevel

- Coating Aperture Up to the Knife-Edge

- Enhanced Aluminum, Protected Gold and Protected Silver Coating Options

Broadband IR Laser Mirrors

Broadband IR Laser Mirrors

- Greater than 98% Reflectivity from 2 - 20μm

- Copper Substrate Mirrors

- High Damage Thresholds

Excimer Laser Line Mirrors

Excimer Laser Line Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- High Damage Threshold of up to 1.5 J/cm2

- Low Loss Dielectric Coatings

- Designed for 193nm and 248nm Lasers

Diode Laser Line Mirrors

Diode Laser Line Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- >99.8% Reflectivity at Design Wavelengths

- Excellent Broadband Performance for Range of Wavelengths

- Designed for Common Diode Lasers

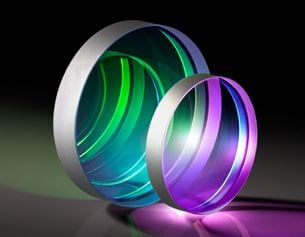

Precision Broadband Laser Mirrors

Precision Broadband Laser Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- Ideal for Tunable Lasers and Reflecting Multiple Laser Sources

- High Reflectivity from 0 - 45° for All Polarization States

- Variety of Coating Options Available

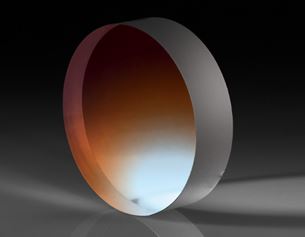

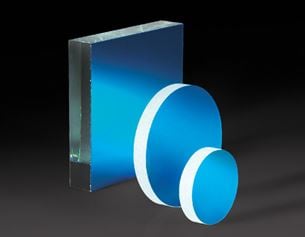

Laser Mirror Substrates

Laser Mirror Substrates

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

- λ/10 Surface Flatness and 10-5 Surface Quality

- High Quality Fused Silica Substrates

- Imperial Sizes with Circular or Rectangular Geometries

- Window Substrates Also Available

Visible Laser Diode Mirrors

Visible Laser Diode Mirrors

- Over 95% Reflectance of Visible Laser Diode Light

- Ideal for Multiple Reflection Systems

- Coating Optimized for 633nm at 45° AOI

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023 | Edmund Optics, Ltd Unit 1, Opus Avenue, Nether Poppleton, York, YO26 6BL, UK

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act