TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

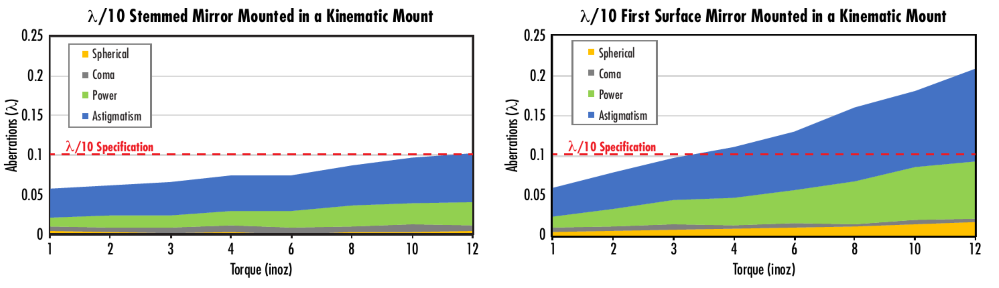

TECHSPEC® Broadband Dielectric Stemmed Mirrors provide low mounting stress and excellent reflectance on high performance, broadband dielectric coated mirrors. Designed to be mounted to TECHSPEC® Kinematic Circular Optical Mounts and E-Series Kinematic Optical Mirror Mounts, all contact between the mirror and the kinematic mount is through the stem, reducing the stress imparted on the optical surface of the mirror. Due to their stress-reducing design and monolithic fused silica construction, these mirrors provide excellent thermal stability and improved surfaced flatness compared to traditionally mounted λ/10 flat mirrors. Featuring greater than 99% reflectivity and 20-10 surface quality, these dielectrically stemmed mirrors perform significantly better than metal coated mirrors and increase system performance by minimizing energy loss and scatter. TECHSPEC® Broadband Dielectric Stemmed Mirrors are available at broad wavelength ranges, can be easily mounted and integrated into optical systems, and are ideal for high power beam steering applications from the UV to the near-infrared spectra.

Note: Contact us for custom options.

Edmund Optics offers comprehensive custom manufacturing services for optical and imaging components tailored to your specific application requirements. Whether in the prototyping phase or preparing for full-scale production, we provide flexible solutions to meet your needs. Our experienced engineers are here to assist—from concept to completion.

Our capabilities include:

Learn more about our custom manufacturing capabilities or submit an inquiry here.

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2025 | Edmund Optics BV, De Maas 22B, 5684 PL Best, The Netherlands

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act

The FUTURE Depends On Optics®